Printed Structural Nodes

Next generation bespokes structures using 3D printingclient: various

my role/scope: parametric structural node design, fabrication (using MarkForged), assembly

type: full time (Laufs Engineering Design)

Project 1. Phyllotaxis Gridshell

At Laufs Engineering Design, I worked closely with engineers throughout the day, where we rejected the practice of "engineering after design" prevalent in the architecture industry. My work covered facade detailing, structural design and programming printable structures.

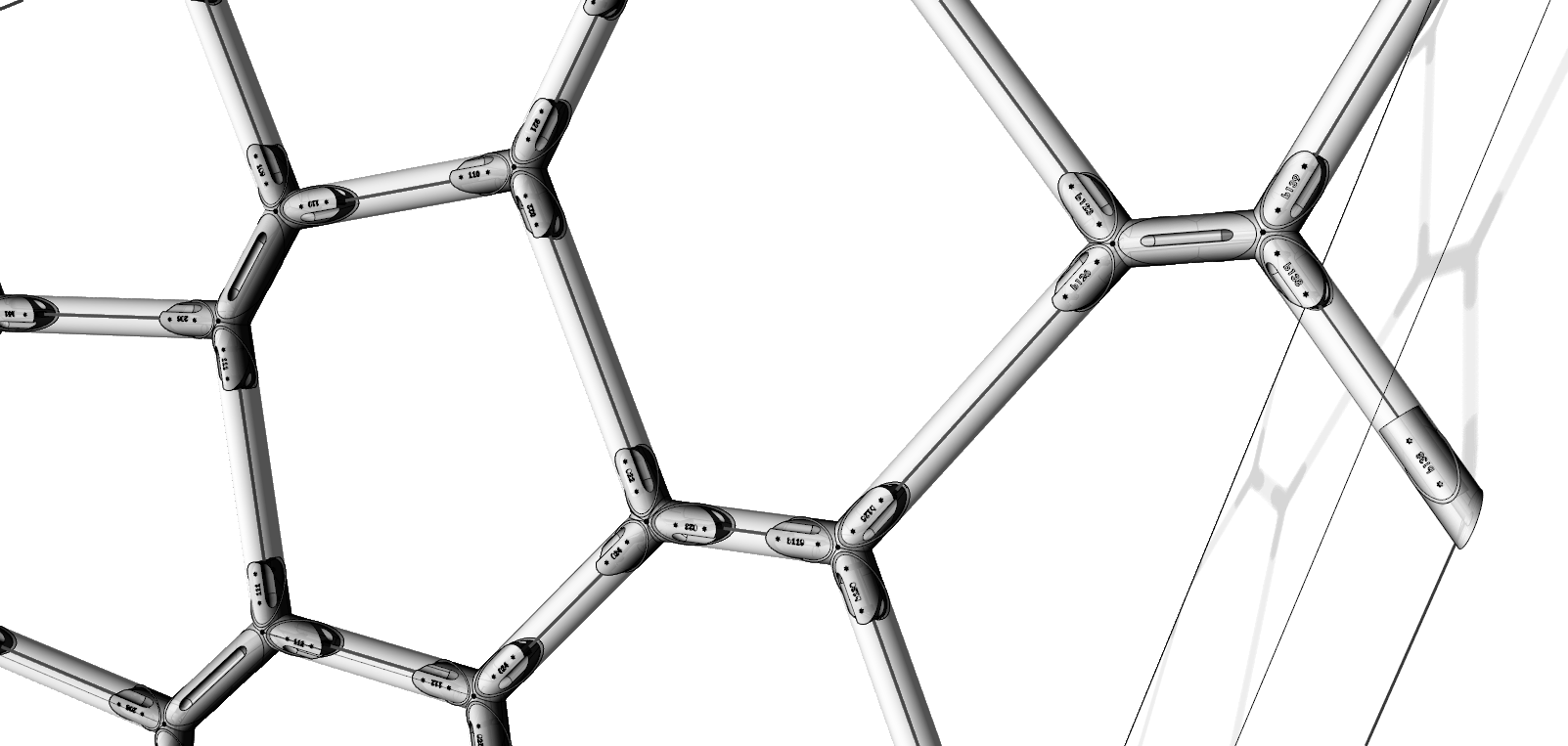

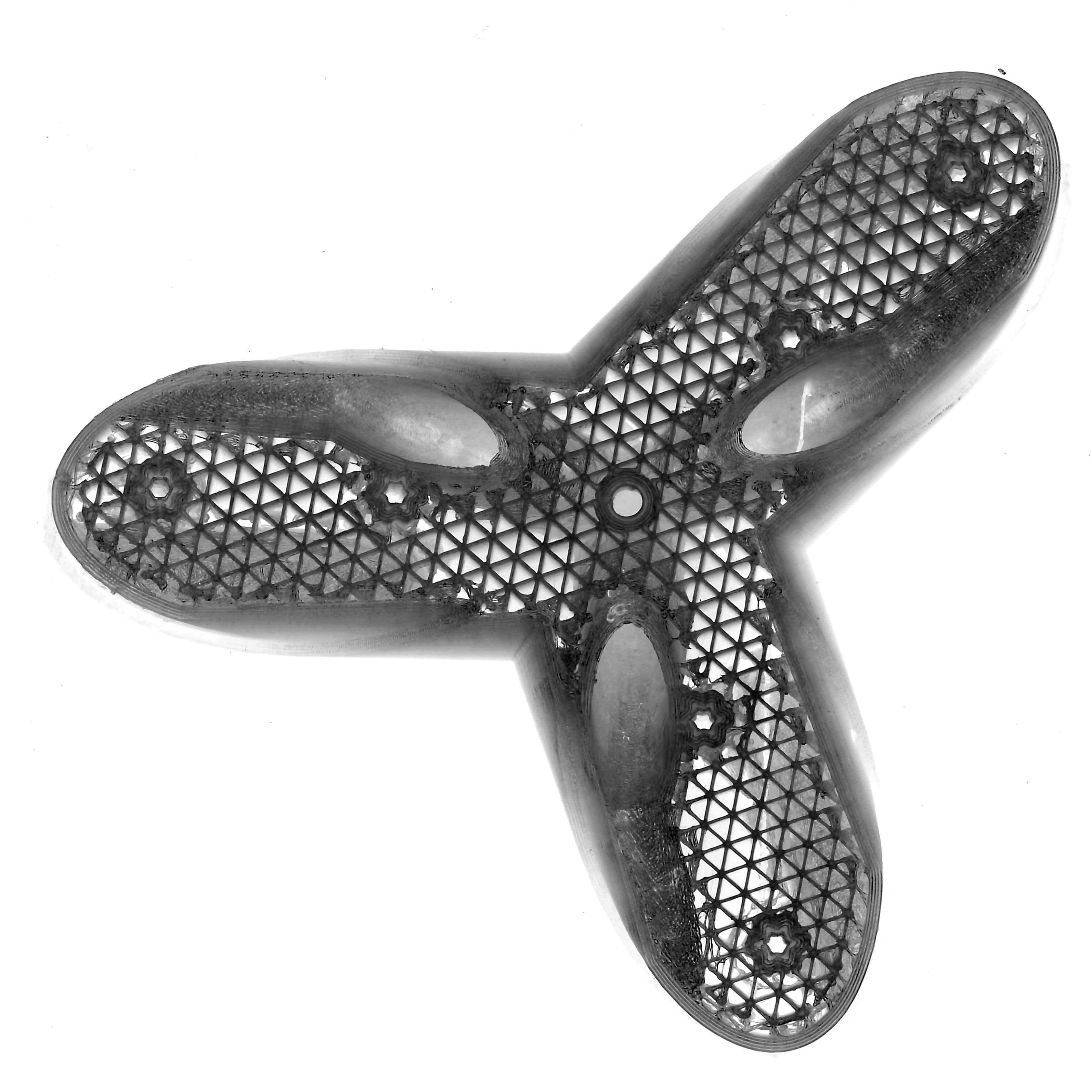

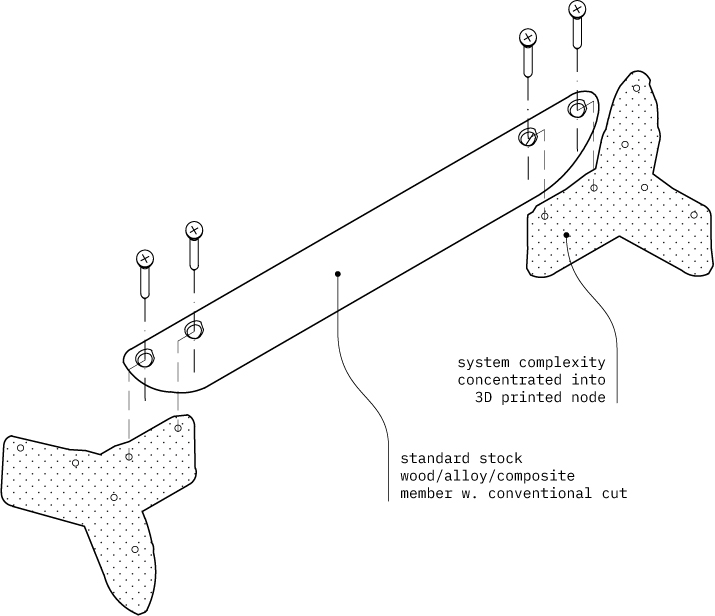

I lead the firm's efforts to develop structurally-performing 3D printed connections for an amorphous grid shell—a task that involved command of 3D and algorithmic tools and a hands-on understanding of structural principles. The aim was to concentrate as much compelxity as possible into the structural nodes thus allowing connecting members to be low-cost stock materials and because the printer doesn’t “care” about repeatability or economies of scale, each node was unique. I wrote a program in Grasshopper that generated nodes from a centerline geometry model. My job also included fabrication and assembly of the grid shell.

Phyllotaxis Grid Shell Project Team

Design Direction: Will LaufsNode design and fabrication: Jeffrey Montes and Patrick Doyle

Grid shell FEM: Alexey Nefedov

Parametric model: Jeffrey Montes

Project 1: Circle Shade 2ΠR4

Together with Eva Jensen Design, LaufsED designed the winning entry for the anual Socrates Sculpture Park Folly/Function competition, which provides a small budget to design and fabricate a functional object for the park.

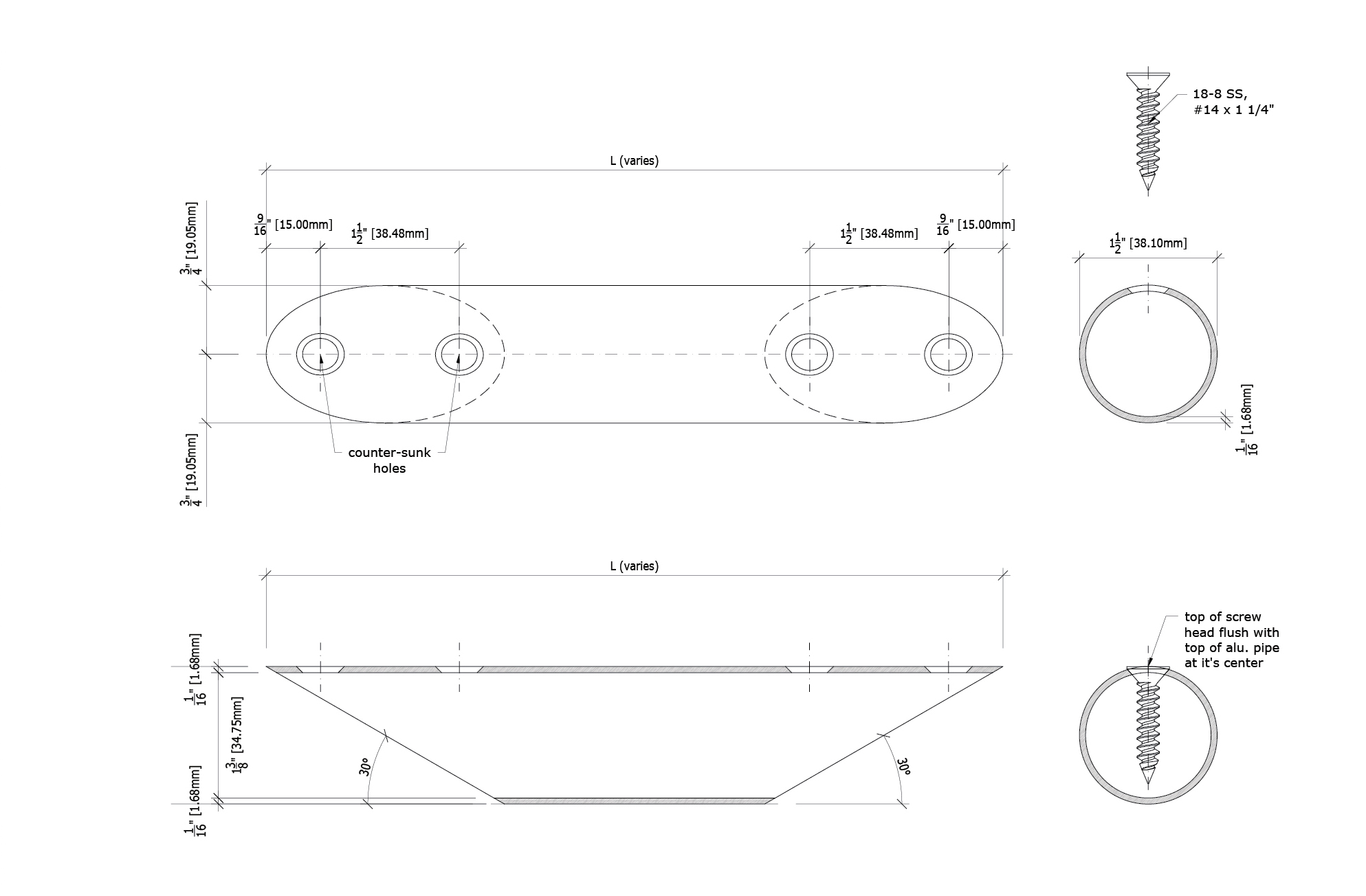

I developed the structural node, connections, and structural details.

Circle Shade Project Team

LaufsED - Jeffrey Montes, Will LaufsEva Jensen Design - Eva Jensen, Sushwala Hedding